One-stop packaging service

Complete machine production

Overall mold, parts, semi-finished, finished product assembly and testing

Our 4 Advantage

New product development to ensure stable injection molding

PCBA development strength

With the development, we have successively established industrial design team, engineering team, operation team, electronic solution team(software and hardware R&D), as well as production supporting equipments (mold、injection、SMT workshop, etc.). About 95 people, including 32 R&D and technical; and 9 operation personnel.

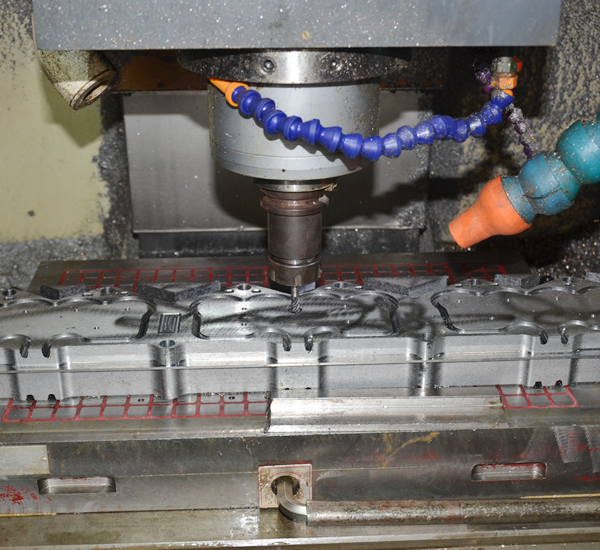

Mold, injection molding processing strength

Mold, injection molding processing equipment has Nisei, Sumitomo Heavy Industries, Haitian, Liansheng and other well-known brand injection molding machine a total of 31 sets, machine tonnage 30T-1500T, daily capacity of 110000 sets, can meet the requirements of high-precision product injection.

Quality control strength

Perfect quality control system, with two element microscope, gear testing machine, projection measuring machine, dynamic balance tester, hardness tester, salt spray tester and other 17 kinds of testing tools,

Strictly implement the testing process, and the product testing process is not less than 6, to ensure the accuracy and stability of the product to meet customer requirements.

Technical team strength

More than 10 years of industry experience of the senior technical team, more than 13 Fortune 500 enterprises service experience, to provide you with professional technical one-to-one service.

50 technical production team with an average working experience of 13 years. Mature technical experience, can control every fine requirements.

What services can we provide for you

Specializing in ODM and OEM, integrates industrial design, software and hardware development, plastic mold and injection molding production, SMT, assembly ect

0755-27326400

0755-27326400